🔍 Key Features

- Material / Composition: High-grade alloy steel, stainless steel, bronze, or custom-specified materials

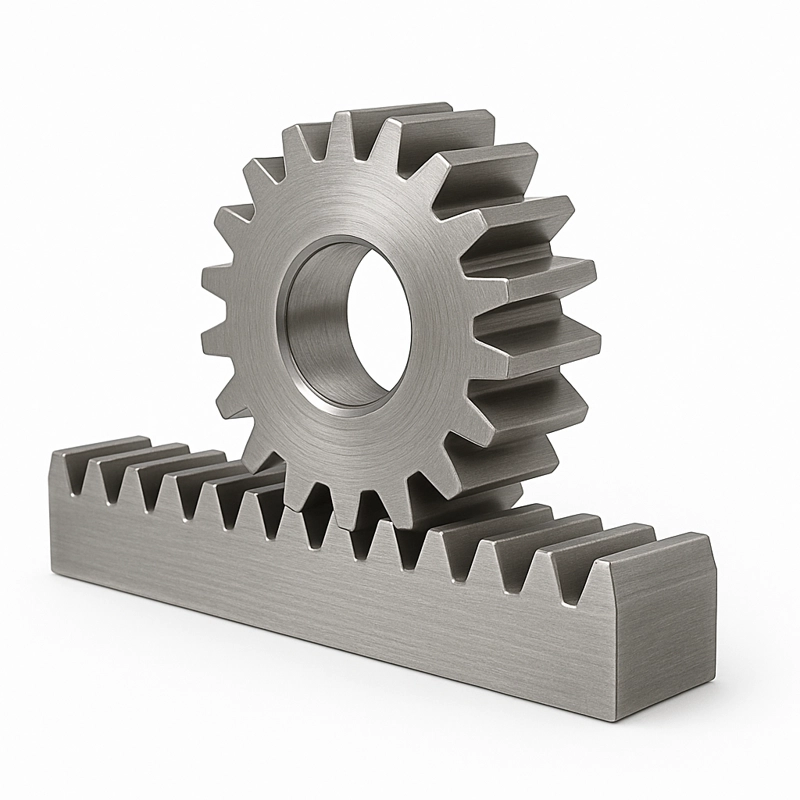

- Core Functionality: Transmits motion and torque with high efficiency and low backlash

- Design or Variations: Spur, helical, bevel, worm, planetary – available in metric and imperial dimensions

- Safety & Compliance: Heat-treated, precision ground, corrosion-resistant, RoHS-compliant

- Customization Options: Tailored tooth profile, bore size, surface coating, and OEM branding available

🎨 Product Variants / Grades / Types

- Spur Gears – Straight-tooth, simple and cost-effective

- Helical Gears – Angled teeth for quieter, smoother motion

- Bevel Gears – Used in angled gearboxes

- Worm Gears – Compact, high-ratio solutions

- Planetary Gear Systems – Ideal for compact and high-torque mechanisms

- Material Grades – EN8, EN24, SS304, SS316, Phosphor Bronze, or as per buyer requirement

- Precision Class – DIN 6–10, AGMA Q9–Q13 (on request)

📦 Accurate Packaging Details

- Standard Packing: Anti-rust coated gears in sealed polybags, packed in sturdy corrugated boxes

- Bulk/OEM Orders: Wooden crates or steel boxes with protective foam lining

- Export-Ready: Palletized, shrink-wrapped, and labeled for international shipment

- OEM Branding: Custom etching, labeling, and packaging available for private brands

🌐 Certifications

- ISO 9001:2015 – Quality Management Systems

- RoHS Compliance – Safe and eco-friendly materials

- CE Certification – For applicable industrial use

- Third-Party Inspection (SGS/TUV) – Available on request

🏭 Ideal Applications / Industries

- Automotive & Transmission Systems

- Industrial Machinery & Automation

- Agricultural Equipment

- Robotics & CNC Machines

- Aerospace Components

- Renewable Energy Systems

Heavy Engineering and OEM assemblies

Reviews

There are no reviews yet.