🔍 Key Features

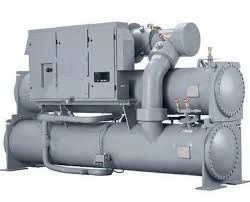

- Material / Composition:

High-quality, durable stainless steel and corrosion-resistant materials for long-lasting performance. - Core Functionality:

Designed to efficiently cool large-scale equipment, systems, or products, maintaining consistent temperatures in demanding environments. - Design / Variations:

Available in air-cooled and water-cooled models, with options for different cooling capacities and energy-efficient systems. - Safety/Compliance Benefits:

Built to comply with international safety standards, featuring overheat protection, pressure relief valves, and low-maintenance requirements. - Customization / Branding Options:

Customizable cooling capacities, electrical configurations, and designs. Option for branding and private labeling to meet client specifications.

🎨 Product Variants / Grades / Types

- Air-Cooled Chillers:

Suitable for environments where water usage is limited or unavailable. - Water-Cooled Chillers:

Ideal for larger systems or industrial plants with abundant water resources, offering higher efficiency. - Custom Chillers:

Tailored units for specific industrial applications with unique capacity and temperature control needs.

📦 Accurate Packaging Details

- Standard Packaging:

Typically packed in wooden crates or sturdy cartons to ensure safe transportation. - Optional/Custom Packing:

Bulk packaging available for OEM orders, including palletized options for easy handling and export. - Palletization or Export-Safe Packing:

Export-safe packaging options to ensure secure delivery across international borders. - OEM/Private Labeling:

Available on bulk orders, with options for custom labeling and branding based on client preferences.

🌐 Certifications

- ISO 9001: Quality management and assurance for consistent product standards.

- CE Marking: Compliance with European Union safety and environmental standards.

- SGS Certification: Guarantees product reliability and quality control measures.

🏭 Ideal Applications / Industries

- Manufacturing Plants:

For cooling machinery and equipment during continuous operations. - Chemical and Pharmaceutical Industries:

Precise cooling for processes and sensitive environments. - Food Processing:

Cooling systems to maintain proper temperature levels in production lines. - Textile Mills:

Maintaining stable temperatures for equipment and processing units. - HVAC Systems:

Used in large-scale HVAC systems for cooling buildings or facilities.

Reviews

There are no reviews yet.