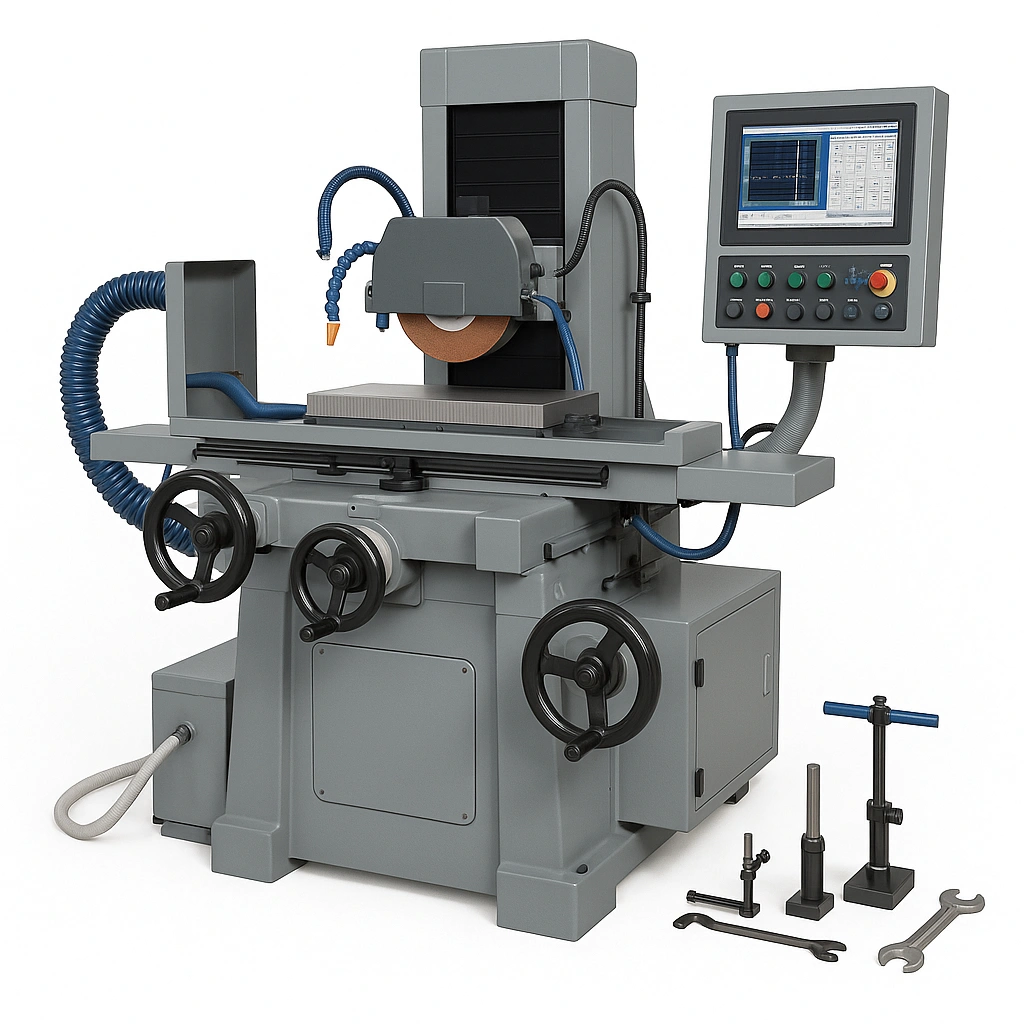

🔍 Key Features

- Material / Composition

Constructed with high-quality metals and alloys to ensure durability, longevity, and high-performance grinding. - Core Functionality or Use

Used to grind and polish materials with precision, these machines are ideal for fine-tuning shapes, edges, and surfaces to meet specific engineering and manufacturing standards. - Design or Variations

Available in various designs, including cylindrical, surface, and internal grinders, to meet the specific needs of diverse industries. Customizable to support different spindle speeds, sizes, and motor capacities. - Safety/Compliance Benefits

Built with safety features including emergency stop buttons, overload protection, and noise reduction systems to comply with international safety standards. - Customization or Branding Options

Available for customization with specific grinding wheels, motors, and operational settings to fit individual production requirements. Option for private labeling and OEM branding on bulk orders.

🎨 Product Variants / Grades / Types

- Surface Grinding Machines: For flat and precise surface finishes.

- Cylindrical Grinding Machines: For grinding circular objects and creating accurate cylindrical surfaces.

- Internal Grinding Machines: Ideal for grinding internal surfaces and holes.

- Universal Grinding Machines: Versatile machines that can be used for multiple grinding operations.

- Custom Options: Available upon request for specific grinding requirements (e.g., size, capacity, motor type).

📦 Accurate Packaging Details

- Standard Packaging: Machines are securely packed in wooden crates or cartons for safe delivery.

- Optional/Custom Packing: Bulk orders or custom machines can be packed according to client specifications, including protective wrapping or custom foam inserts.

- Palletization or Export-Safe Packing: Export-friendly packaging ensures safe transit, including moisture protection and reinforced pallets.

- OEM/Private Labeling: Available for OEM and private labeling upon request for large or customized orders.

🌐 Certifications

- ISO 9001: Ensuring high-quality standards in manufacturing processes.

- CE Certified: Compliant with European health, safety, and environmental protection standards.

- BIS (Bureau of Indian Standards): Conforming to Indian safety and quality standards.

🏭 Ideal Applications / Industries

- Automotive Manufacturing: Precision grinding for engine parts and mechanical components.

- Aerospace: Grinding of turbine blades and other critical parts requiring high precision.

- Metalworking and Fabrication: For surface finishing and polishing metal components.

- Tooling and Die Making: Ideal for grinding molds, dies, and cutting tools.

- Electronics Manufacturing: Grinding of small and delicate electronic components.

Reviews

There are no reviews yet.