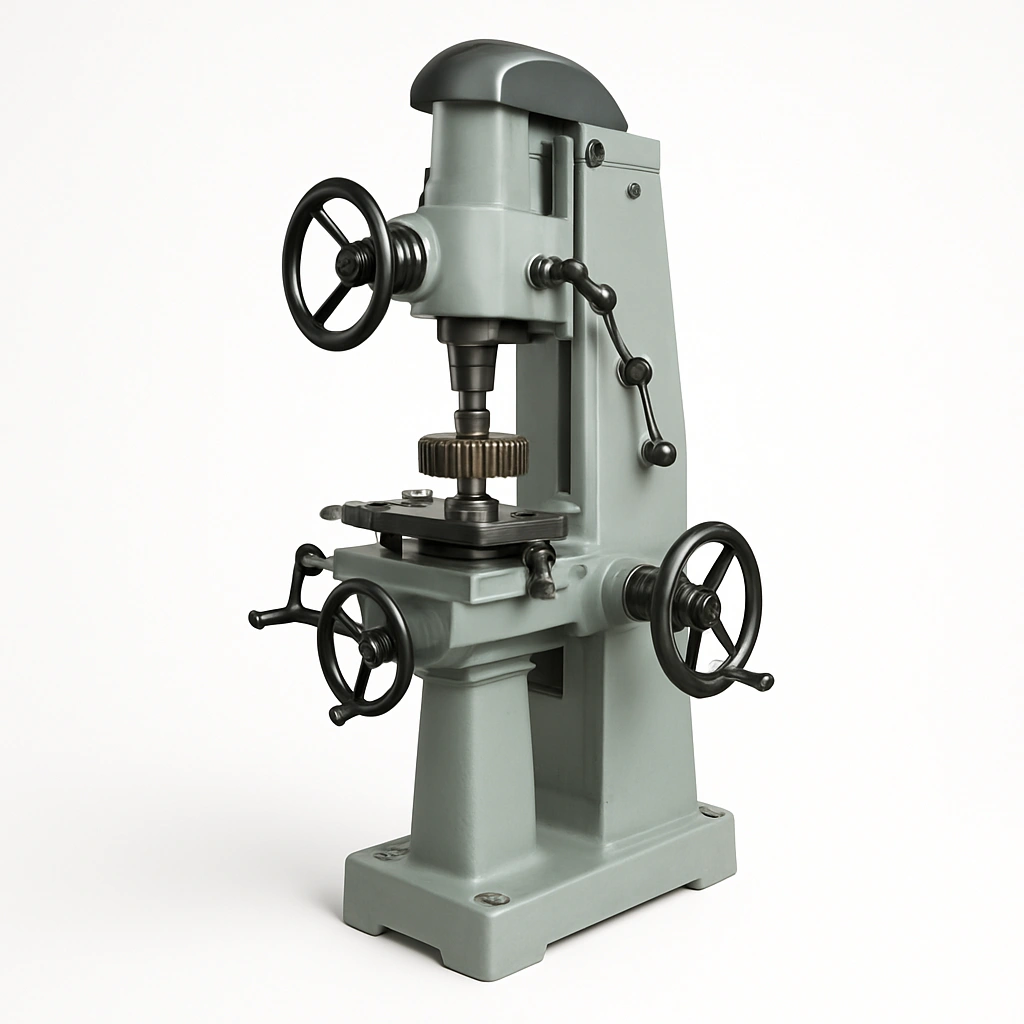

🔍 Key Features

- Material / Composition: Made from high-quality alloy steel and durable components to ensure longevity and resistance to wear.

- Core Functionality: Primarily used to cut gears, splines, and other related components with precision, enabling high-performance results in automotive, machinery, and heavy equipment sectors.

- Design / Variations: Available in various models, including CNC (Computer Numerical Control) and conventional gear cutters, catering to different production needs.

- Safety / Compliance Benefits: Equipped with safety features such as automatic shut-off, protective covers, and ergonomic controls, meeting global safety standards.

- Customization or Branding Options: Machines can be customized with specific cutting tools, software, and user interface options to match your production requirements. Private labeling options available for OEMs.

🎨 Product Variants / Grades / Types

- CNC Gear Cutting Machines: For automated, high-precision gear manufacturing.

- Manual Gear Cutting Machines: Ideal for small-scale production and prototyping.

- Hobbers: For cutting helical gears, bevel gears, and more.

- Shapers: For precise shaping of gears with varying tooth profiles.

📦 Accurate Packaging Details

- Standard Packaging: Machines are packed securely in wooden crates or pallets, depending on size.

- Optional/Custom Packing: Available for bulk or OEM orders, including custom packaging options for large-scale shipments.

- Palletization/Export-Safe Packing: Heavy-duty, export-ready packaging with reinforced pallets for global shipments.

- OEM/Private Labeling: Available upon request for OEM or private labeling for distributor clients.

🌐 Certifications

- ISO 9001: Quality management system standards.

- CE Certification: Compliance with European safety, health, and environmental protection standards.

- SGS Certification: Ensures machines meet international manufacturing and quality standards.

🏭 Ideal Applications / Industries

- Automotive Manufacturing: Essential for producing precision gears for engines and transmissions.

- Industrial Equipment: Used for cutting gears and parts in heavy machinery.

- Aerospace: For high-precision components requiring strict tolerances.

- Agricultural Machinery: Gear cutting machines support the manufacturing of durable parts for farming equipment.

- Renewable Energy: Essential in creating parts for wind turbines and other energy generation machinery.

Reviews

There are no reviews yet.